Cold Storage Flooring in Pakistan

Introduction

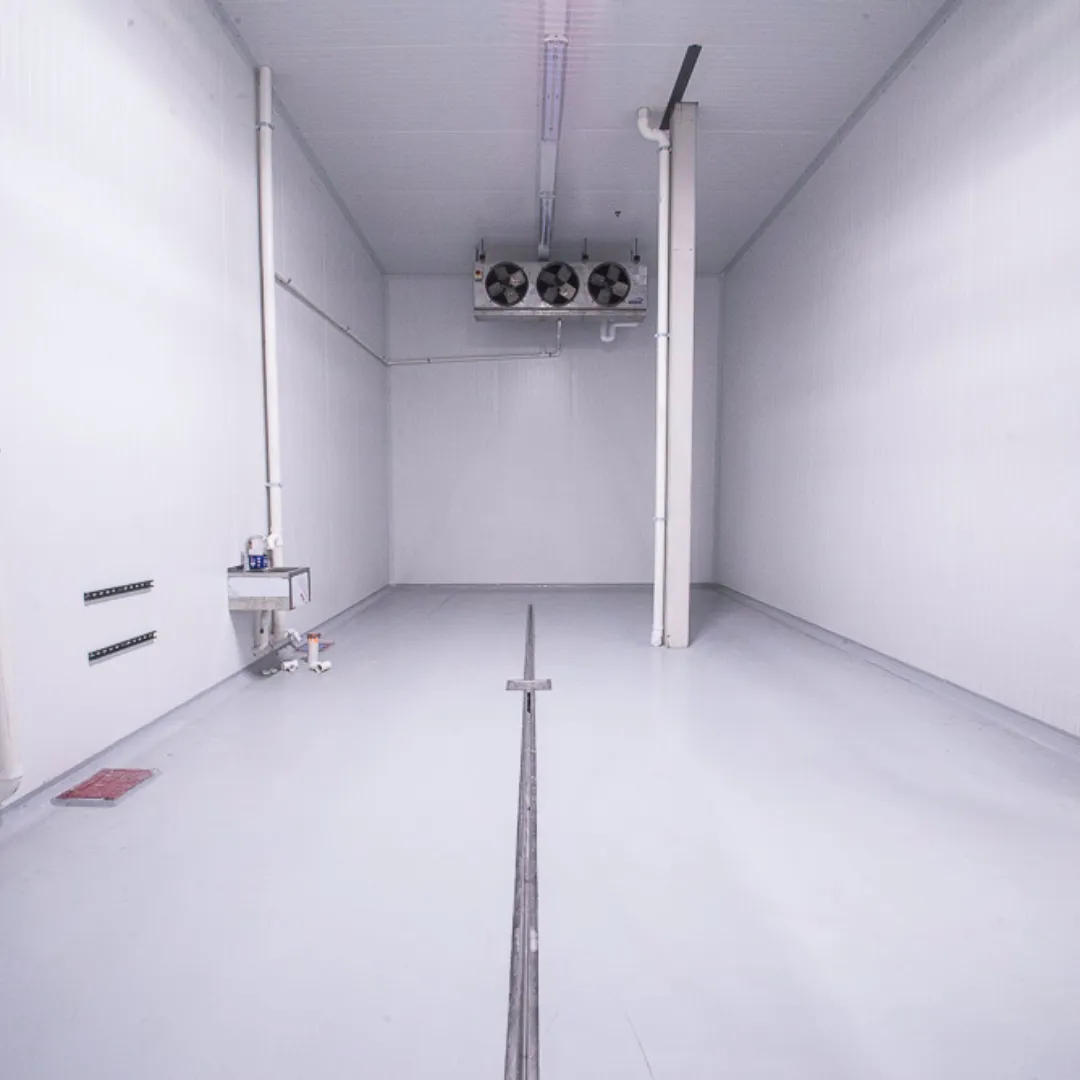

Cold storage facilities play a critical role in Pakistan’s logistics, food, and pharmaceutical industries. From frozen foods and dairy products to vaccines and medical supplies, maintaining temperature-controlled environments is essential for product safety and compliance.

However, one often overlooked aspect of cold storage design is flooring — the foundation that directly affects insulation, hygiene, and durability.

Choosing the right cold storage flooring in Pakistan is not only about aesthetics; it’s about selecting a system that can withstand freezing temperatures, heavy loads, moisture, and constant traffic while maintaining a hygienic, non-slip, and seamless surface.

This guide explores the best flooring systems for cold storage facilities in Pakistan, their benefits, installation techniques, and key considerations for long-term performance.

Why Cold Storage Flooring Matters?

Cold storage flooring is exposed to some of the harshest industrial conditions:

- Extreme temperature changes

- Heavy forklift movement

- Condensation and moisture exposure

- Chemical and cleaning agent contact

An inappropriate flooring system can lead to cracking, peeling, delamination, or loss of insulation — all of which compromise the storage environment and increase operational costs.

A well-designed cold room floor ensures:

- Thermal insulation and energy efficiency

- Seamless hygiene (no bacterial growth)

- Slip resistance in icy conditions

- Durability under heavy mechanical loads

- Easy cleaning and low maintenance

Key Requirements for Cold Storage Flooring

For flooring to perform efficiently in Pakistan’s varying climate and cold storage applications, it must meet specific standards. These include:

- Thermal Shock Resistance: Ability to withstand temperature fluctuations from +30°C to -40°C.

- Moisture Resistance: Prevents condensation-related damage and microbial growth.

- Slip Resistance: Essential for worker safety on wet or icy surfaces.

- Chemical Resistance: Protection against cleaning agents, brine, and organic acids.

- Load Bearing Strength: Must handle pallet jacks, forklifts, and heavy racks.

- Hygienic Surface: Seamless, non-porous, and easy to clean.

Best Flooring Options for Cold Storage in Pakistan

Here are the most effective and industry-proven flooring systems suitable for Pakistan’s cold storage and freezing facilities:

1. Polyurethane (PU) Flooring

PU flooring is the most preferred solution for cold storage areas due to its thermal shock resistance and durability. It remains flexible at sub-zero temperatures and can withstand frequent washdowns.

Key Benefits

- Performs well in freezing environments

- High resistance to chemicals and abrasion

- Seamless and hygienic

- Available in anti-slip finishes

Recommended For

Food processing, meat storage, dairy plants, frozen goods storage.

2. Epoxy Flooring

Epoxy flooring offers a smooth, durable, and easy-to-clean surface, making it ideal for ambient or moderately cold areas. However, it’s less suitable for extreme freeze-thaw conditions compared to PU systems.

Key Benefits

- Glossy, seamless appearance

- Chemical and impact resistance

- Cost-effective installation

Recommended For

Chilled storage (above 0°C), packing areas, and logistics zones connected to cold rooms.

3. Urethane Cement Flooring

Also known as PU Concrete, this system combines polyurethane resin with cementitious aggregates for exceptional performance in cold environments.

Key Benefits

- Handles temperatures from +120°C to -40°C

- Excellent impact and chemical resistance

- Non-slip and seamless finish

Recommended For

Freezers, blast chillers, and high-traffic cold storage zones.

4. MMA (Methyl Methacrylate) Flooring

MMA flooring is known for ultra-fast curing, allowing quick installation even in low-temperature environments. It’s an excellent option for facilities that can’t afford long shutdowns.

Key Benefits

- Cures in freezing conditions

- High strength and chemical resistance

- Textured finish for slip prevention

Recommended For

Renovations or quick repairs in operational cold stores.

5. Insulated Concrete with Vapor Barriers

In facilities requiring heavy insulation, insulated concrete slabs with vapor barriers and resin coatings provide long-term stability. This system helps prevent condensation, frost heave, and energy loss.

Key Benefits

- Excellent thermal insulation

- Prevents moisture migration

- Structural stability under heavy loads

Recommended For

Large-scale cold storage warehouses and food logistics centers.

Flooring Type Comparison

| Flooring Type | Durability | Thermal Resistance | Chemical Resistance | Slip Resistance | Installation Speed |

|---|---|---|---|---|---|

| PU Flooring | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | Moderate |

| Epoxy Flooring | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | Moderate |

| Urethane Cement | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Longer |

| MMA Flooring | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | Fast |

| Insulated Concrete | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★☆☆ | Longer |

Common Problems and Solutions

Even with high-quality materials, poor preparation or installation can cause flooring failures. Below is a troubleshooting table:

| Problem | Cause | Prevention / Fix |

|---|---|---|

| Cracking or delamination | Thermal shock or moisture in slab | Use PU or urethane cement; ensure vapor barrier and priming |

| Condensation or frost buildup | Poor insulation or air leakage | Use insulated concrete slabs and seal joints |

| Slippery surface | Smooth finish with condensation | Add anti-slip aggregates or textured coatings |

| Surface wear or fading | Heavy traffic or harsh cleaning agents | Use chemical-resistant topcoats and proper cleaning agents |

Cost Factors for Cold Storage Flooring in Pakistan

The cost varies based on materials, thickness, and insulation needs. Below is an overview:

| Cost Factor | Impact on Budget |

|---|---|

| Flooring Material | Main cost (Epoxy, PU, Urethane) |

| Insulation & Vapor Barriers | Adds cost but essential for performance |

| Surface Preparation | Improves adhesion and durability |

| Area Size | Larger areas reduce per-sq-ft cost |

| Temperature Range | Lower temperatures require advanced systems |

Installation Process

Installing cold storage flooring involves several crucial steps to ensure performance and longevity:

Surface Preparation

Grinding, shot blasting, and cleaning to remove contaminants.Moisture Control

Applying moisture barrier coatings or membranes.Insulation & Vapor Barrier Installation

Essential for maintaining temperature and preventing frost heave.Primer Application

Promotes adhesion between substrate and resin system.Flooring System Application

Multiple layers of epoxy, PU, or urethane cement applied.Topcoat & Finishing

Slip-resistant, chemical-resistant topcoat added for durability.

Maintenance Tips

To extend the lifespan of your cold storage flooring:

- Maintain consistent temperature and humidity levels.

- Use mild detergents for cleaning.

- Avoid sharp impacts or dragging heavy metal objects.

- Inspect expansion joints periodically.

- Recoat top layers every few years if needed.

Applications of Cold Storage Flooring in Pakistan

Cold storage flooring systems are widely used across Pakistan’s industrial sectors, including:

- Food & Beverage Cold Stores

For frozen meat, dairy, and processed foods. - Pharmaceutical Cold Rooms

For vaccines, medicines, and temperature-sensitive materials. - Fruit & Vegetable Cold Warehouses

Helps maintain freshness and shelf life. - Seafood and Meat Processing Plants

Ensures hygiene and easy cleaning. - Cold Logistics & Distribution Centers

For smooth material handling and thermal control.

Advantages of High-Quality Cold Storage Flooring

- Enhanced hygiene and cleanliness

- Slip-resistant and safe working environment

- Long lifespan with minimal maintenance

- Excellent insulation and energy efficiency

- Withstands heavy machinery and temperature shifts

Conclusion

Cold storage flooring in Pakistan requires a balance of durability, hygiene, insulation, and chemical resistance. PU and urethane cement systems stand out as the most reliable solutions for long-term performance under extreme temperature conditions.

Whether you’re building a food cold room in Karachi, a pharmaceutical warehouse in Lahore, or a distribution hub in Islamabad, investing in the right flooring system ensures energy efficiency, safety, and operational reliability.

For expert consultation and installation of cold storage flooring systems in Pakistan, work with professional flooring contractors experienced in epoxy, polyurethane, and insulated concrete flooring solutions.

FAQ'S

PU or urethane cement flooring is best due to their ability to perform in freezing temperatures and resist chemical and thermal stress.

Epoxy can be used in chilled storage areas (above 0°C), but for sub-zero environments, PU or urethane cement is more reliable.

Use flexible, thermally stable flooring systems with a vapor barrier and ensure proper surface preparation.

Costs depend on materials and temperature range. PU and urethane cement are more expensive but offer long-term savings through durability.

With proper installation and maintenance, it can last 10–20 years or more.