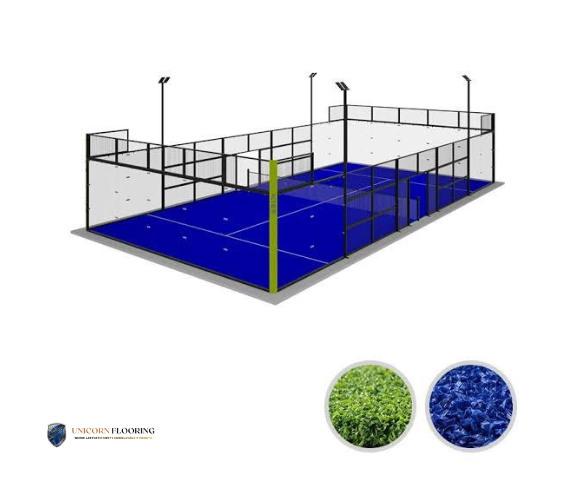

Premium Quality Pedal Court

Pedal Court Price in Pakistan

| Type of Pedal Court | Estimated Cost Range (Rs) |

|---|---|

| Pedal court with imported turf | 45 lacRs – 50 lac Rs |

| Pedal court with local turf | 35 lac Rs – 40 lac Rs |

| Pedal court with acrylic paint | 25 lac Rs – 30 lac Rs |

Pedal Court Turf Price in Pakistan

| Type of Turf | Price (Rs) |

|---|---|

| Bell in turf | 7,500,000 Rs |

| Local turf | 550,000 Rs |

Standard Pedal Court Cost in Pakistan

| Component | Cost (Rs) |

|---|---|

| Pedal court RCC base structure | 8 lakh Rs |

| Pedal court super steel structure | 9 lakh Rs |

| Pedal court glass work | 7.5 lakh Rs |

| Pedal court astro turf | 7.5 lakh Rs |

| Electrical work | 2 lakh Rs |

| Padel court other work | 1.5 lakh Rs |

Pedal Court Installation in Pakistan

Padel Court Installation is a structured process that begins with a thorough site assessment to determine space, soil quality, and drainage needs. Once the location is prepared, the ground is excavated and a solid foundation is constructed to ensure long-term stability. A proper drainage system is then installed to prevent water buildup, followed by the placement of the base layers and artificial turf. After the flooring is secured, the glass walls, metal structures, and fencing are assembled with precision to meet safety standards. Lighting systems and net posts are installed next, completing the court’s functional elements. The final steps include court marking, detailed quality checks, and safety inspections to ensure the court is fully ready for play. This step-by-step approach guarantees a high-quality, durable, and professional padel court installation.

Types of Pedal Court Sructure

In Pakistan, padel courts are available in several structural types to suit different environments, budgets, and performance needs. The most common are panoramic padel courts, which feature open-back designs with minimal metal frames, offering unobstructed visibility and a premium playing experience—ideal for clubs and commercial complexes. Standard or classic padel courts use framed glass panels supported by steel columns, providing durability and cost-effectiveness for community centers and private installations. Portable or modular padel courts are also gaining popularity, allowing easy assembly and relocation for events and short-term setups. Additionally, covered or semi-indoor padel courts are becoming more common in regions with extreme weather, offering protection from heat, rain, and dust. Together, these structure types cater to Pakistan’s diverse climate conditions and growing demand for professional and recreational padel facilities.

Sub Base Structure

1. Site Marking & Excavation

Superstructure

1. Padel Court Frame

- Supply Steel Sections: Bring 4”×4” and 4”×2” square hollow sections for the frame.

- Fabricate Frame: Cut and weld steel sections as per the 66 ft × 33 ft design.

- Assemble Structure: Put together the frame on-site, ensuring all parts fit correctly.

- Check Alignment: Ensure the frame is straight, level, and properly squared.

- Surface Preparation: Clean and prepare the steel for painting.

- Apply Primer and Paint: Coat the frame with primer and corrosion-resistant paint for durability.

2. Main / Longitudinal Pipes

- Supply Pipes: Bring 4” × 4”, 12 SWG steel pipes with a total length of 250 ft.

- Cut to Size: Cut the pipes as required for installation.

- Position Pipes: Lay the pipes along the main/longitudinal lines of the structure.

- Secure in Place: Fix and align the pipes properly to ensure stability.

- Prepare for Next Steps: Pipes are ready for connection to other structural or functional elements.

3. Sub Pipes

- Supply Pipes: Provide 4” × 2”, 14 SWG steel pipes with a total length of 330 ft.

- Cut to Size: Cut the pipes according to the required measurements.

- Position Pipes: Lay the sub pipes in the designated locations under or across the main frame.

- Secure and Align: Ensure proper alignment and stability of all sub pipes.

- Ready for Integration: Pipes are now ready to connect with the main pipes or other structural elements.

4. Iron Mesh Panel

- Supply Panels: Provide iron mesh panels sized 3 m × 2 m.

- Use Steel Bars: Construct the mesh using 1” × 1”, 14 SWG steel bars.

- Total Material: Total steel length used = 950 ft.

- Assemble Panels: Weld or fix bars to form strong, uniform mesh panels.

- Install Panels: Place and secure panels at designated positions on the court or fencing structure.

- Check Alignment: Ensure all panels are straight, level, and properly fixed.

5. Electro Welded Mesh

- Mesh Size: 50 mm × 50 mm squares.

- Steel Thickness: 12 SWG (0.125’’ thick) for strength and durability.

- Material Type: Galvanized dipped to resist corrosion.

- Use: Can be used for fencing, reinforcement, or protective panels.

- Installation: Panels are cut, positioned, and securely fixed as required.

6. Fabrication Cost

- Cutting: Cutting mild steel sections to the required sizes.

- Drilling: Making holes for bolts, connections, or fixtures.

- Pre-Assembly: Partially assembling the frame before final installation.

- Handling: Moving, lifting, and positioning steel components safely on-site.

- Cost Coverage: All these activities are included in the fabrication cost of the mild steel frame.

7. Structural Steel

- Surface Preparation: Clean and prepare steel surfaces before painting.

- Apply Primer: Coat the steel with a protective primer to prevent rust.

- Topcoat Application: Apply one or more layers of topcoat paint for durability and appearance.

- Full Finishing: Ensure smooth, even coverage on all visible surfaces for a professional finish.

- Protection: The painting process enhances corrosion resistance and longevity of the steel structure.

Glasswork

1. Glass Panel

- Supply Glass: Provide tempered glass panels, 10 mm or 12 mm thick.

- Panel Size: Each panel measures 3 m × 2 m.

- Quantity: Total of 18 panels.

- Install Panels: Place and secure panels in the frame or designated structure.

- Check Alignment: Ensure panels are straight, level, and properly fixed.

- Safety: Use tempered glass for durability and impact resistance.

2. Bottom Patch Fitting

- Purpose: Bottom patch fittings are used to secure the lower part of glass doors or panels.

- Supply Fittings: Provide high-quality stainless steel or aluminum bottom patch fittings.

- Position Fittings: Align the fittings at the base of the glass panel or door.

- Fix Securely: Bolt or clamp the glass into the fittings to hold it firmly in place.

- Check Alignment: Ensure the panel is level and moves smoothly if it’s a door.

- Finish: Make sure all fittings are tight and provide a neat, safe finish.

3. Top / Over Patch Panel Fitting

- Purpose: Top or over patch fittings secure the upper part of glass doors or panels.

- Supply Fittings: Provide durable stainless steel or aluminum top/over patch fittings.

- Position Fittings: Align the fittings at the top edge of the glass panel or door.

- Fix Securely: Bolt or clamp the glass into the fittings for stability.

- Check Alignment: Ensure the panel or door is level, properly aligned, and can swing/move smoothly if needed.

- Finish: Tighten all fittings and ensure a neat, safe, and professional finish.

4. Glass-to-Glass Connector (90°)

- Purpose: Connects two glass panels at a 90° angle, typically for corners of the court or doors.

- Supply Connector: Provide high-quality stainless steel or aluminum 90° glass connectors.

- Position Connector: Align the connector precisely where the two glass panels meet.

- Fix Securely: Clamp or bolt both glass panels into the connector to hold them firmly.

- Check Alignment: Ensure panels form a perfect 90° angle and are level.

- Finish: Tighten all fittings for a safe, neat, and professional corner joint.

5. Floor Hinges (for doors)

- Purpose: Floor hinges allow glass doors to pivot smoothly at the floor level.

- Supply Hinges: Provide high-quality floor hinges suitable for the weight of the glass door.

- Position Hinges: Install hinges at the designated spots on the floor beneath the door.

- Fix Securely: Anchor the hinges firmly into the floor for stability.

- Attach Door: Mount the glass door onto the hinges carefully.

- Check Operation: Ensure the door swings smoothly and returns to the closed position properly.

- Finish: Tighten all bolts and ensure a neat, safe, and professional installation.

6. Miscellaneous Fittings (brackets, anchors, silicone, gaskets, screws)

- Brackets: Provide and install brackets to support panels, frames, or fixtures.

- Anchors: Use anchors to securely fix structures to walls, floors, or frames.

- Silicone: Apply silicone for sealing gaps, waterproofing, and cushioning glass panels.

- Gaskets: Install gaskets to protect glass edges, prevent rattling, and ensure tight joints.

- Screws and Fasteners: Use appropriate screws and fasteners to assemble and secure all components.

- Check Functionality: Ensure all fittings are correctly installed, secure, and aligned for a safe and professional finish.

7. Installation & Labour & Finishing

- Skilled Labor: Engage trained personnel for assembling and installing all court components.

- Panel & Frame Installation: Erect steel frames, install glass panels, mesh, doors, and fittings.

- Alignment & Leveling: Ensure all elements are straight, level, and properly aligned.

- Tightening & Securing: Fasten all bolts, screws, and fittings securely.

- Surface Finishing: Smooth edges, touch up paint, clean surfaces, and remove debris.

- Quality Check: Inspect the entire installation to ensure safety, durability, and a professional finish.

Astro Turf Flooring

1. Supply & Install Artificial Turf (Sports Grade) Blue Color

- Supply Turf: Provide sports-grade artificial turf in blue color.

- Prepare Base: Ensure the underlying surface (PCC slab, sand layer, etc.) is clean, level, and smooth.

- Lay Turf: Roll out the artificial turf over the prepared base.

- Trim & Align: Cut and fit the turf precisely to cover the entire playing area.

- Join Seams: Secure seams using adhesive or tape to make a continuous surface.

- Fix Edges: Anchor the edges firmly to prevent lifting or movement.

- Final Finishing: Brush the turf fibers, check alignment, and ensure a neat, even surface ready for play.

2. Astro Turf Installation Labour

- Site Preparation: Ensure the base is clean, level, and ready for turf installation.

- Unroll Turf: Lay out the artificial turf carefully over the prepared surface.

- Trimming & Cutting: Cut turf to fit the playing area precisely.

- Seam Joining: Join seams using adhesive or tape to create a continuous surface.

- Edge Fixing: Secure all edges to prevent lifting or movement.

- Brushing & Finishing: Brush the turf fibers, check alignment, and make sure the surface is even and smooth.

- Quality Check: Inspect the installed turf to ensure a safe and professional playing surface.

3. Labor for Rolling, Fixing, Leveling, and Securing Synthetic Turf

- Rolling Out Turf: Spread the synthetic turf evenly over the prepared base.

- Fixing in Place: Position the turf accurately and adjust for proper coverage.

- Leveling Surface: Smooth out any bumps or uneven areas to ensure a flat playing surface.

- Securing Edges: Anchor edges and seams to prevent movement or lifting.

- Final Inspection: Check the entire surface to ensure it is uniform, smooth, and ready for play.

Electric Work

1. 200W IP66 Economical LED Floodlights

- Type: 200W LED floodlights.

- Quality: Economical, suitable for outdoor use.

- Weatherproof: IP66 rating ensures protection against dust and heavy rain.

- Installation Location: Mounted around the padel court for proper illumination.

- Purpose: Provide bright, even lighting for evening or night play.

- Durability: Designed to withstand outdoor conditions for long-term use.

2. Floodlight Accessories

- Brackets: Support and hold the floodlights in position.

- Clamps: Secure the floodlights to poles or mounting structures.

- Bolts: Fasten the brackets, clamps, and base plates firmly.

- Base Plate: Provide a stable foundation for mounting the floodlight assembly.

- Installation Check: Ensure all accessories are tightly fixed, aligned, and safe for outdoor use.

3. Distributor / Junction Box (Outdoor Rated, 6-Way)

- Type: Outdoor-rated junction box with 6-way connections.

- Purpose: Distributes electrical power to multiple floodlights or devices safely.

- Installation Location: Mounted in a weather-protected area near the court or on a pole.

- Connections: Provides secure wiring points for incoming and outgoing cables.

- Safety: Ensures proper insulation and protection against rain, dust, and electrical faults.

- Maintenance: Easy access for troubleshooting and future electrical modifications.

4. Electrical Works & Wiring (installation, trenching, mounting)

- Trenching: Dig trenches to lay electrical cables safely underground.

- Cable Laying: Install power cables in the trenches or along mounting routes.

- Mounting Fixtures: Fix junction boxes, floodlights, and other electrical components in place.

- Connections: Connect cables to junction boxes, floodlights, and switches as per design.

- Safety Measures: Ensure proper insulation, grounding, and adherence to electrical standards.

- Testing & Commissioning: Test the complete system for proper operation and safety before use.

5. Power Cable 4-Core 10 mm²

- Type: 4-core power cable with 10 mm² conductor size.

- Purpose: Transmit electrical power to floodlights, junction boxes, and other court equipment.

- Installation: Lay the cable through trenches, conduits, or along mounting paths as required.

- Connections: Connect securely to junction boxes, switches, and fixtures.

- Safety: Ensure proper insulation, grounding, and compliance with electrical standards.

- Testing: Check continuity and voltage to confirm proper functioning after installation.

6. Control / Lighting Cable 3-Core 2.5 mm²

- Type: 3-core cable with 2.5 mm² conductor size.

- Purpose: Used for lighting circuits and control wiring for floodlights or switches.

- Installation: Lay the cable through trenches, conduits, or along mounting paths as needed.

- Connections: Connect to floodlights, junction boxes, and control switches securely.

- Safety: Ensure proper insulation, grounding, and adherence to electrical standards.

- Testing: Verify continuity and proper operation of lighting circuits after installation.

Premium Quality Pedal Court in Pakistan

Padel—often spelled “Pedal” locally—is rapidly becoming one of the most popular racket sports around the world. With its fast-paced gameplay, modern design, and minimal space requirements, more sports clubs, academies, and private properties in Pakistan are investing in premium quality pedal courts. Choosing the right court is not just about having a playing surface; it’s about ensuring durability, safety, and world-class performance.

In this blog post, we will explore what makes a premium pedal court truly outstanding and how Pakistan’s growing sports infrastructure is embracing this trend.

What Makes a Pedal Court “Premium Quality”?

A premium pedal court is designed with advanced engineering, high-quality materials, and a focus on long-term performance. The best courts include:

- Heavy-duty steel or aluminum structure

- Tempered glass panels for maximum visibility and strength

- High-quality artificial turf tailored for fast play

- Shock-absorbent flooring for player safety

- UV-resistant and weatherproof materials suitable for Pakistan’s climate

Whether for a commercial sports facility or a private home, investing in high-quality components ensures that the court remains durable and visually appealing for years.

Pedal Court Construction in Pakistan – A Rapidly Growing Industry

The demand for pedal court construction in Pakistan has increased significantly over the past few years. Sports clubs in Lahore, Karachi, Islamabad, and other major cities are upgrading their facilities to meet international standards.

Professional construction includes:

- Site preparation and leveling

- Steel or aluminum framing

- Glass wall installation

- Turf laying and infill application

- Lighting, fencing, and accessories

- Finishing touches for aesthetics and safety

Choosing an expert builder ensures correct installation and longevity of the court.

Pedal Court Installation in Pakistan – Why Expertise Matters

A court is only as good as its installation. Skilled professionals make sure that:

- The structure is perfectly aligned

- Glass panels are safely secured

- Turf is laid without wrinkles or uneven spots

- Drainage and foundation systems are properly implemented

Improper installation can affect gameplay, safety, and long-term quality, which is why hiring a specialized company is essential.

Pedal Court Manufacturer in Pakistan – Local Expertise, International Quality

Several manufacturers in Pakistan now produce pedal court components that meet global standards. A reliable pedal court manufacturer in Pakistan will offer:

- Imported turf and mesh

- High-strength tempered glass

- Rust-proof frames

- Custom designs for outdoor or indoor courts

- Warranty and after-sales support

Local manufacturing reduces cost while maintaining high quality.

Pedal Court Turf Price – What to Expect

The pedal court turf price in Pakistan varies based on:

- Turf thickness

- Fiber quality

- Infill type (sand, rubber, etc.)

- Brand and origin (local or imported)

Premium turf ensures a smoother ball bounce, better grip, and improved player comfort, which is essential for professional-grade paddle courts.

Pedal Court Price in Pakistan – Budget vs Premium Options

The pedal court price in Pakistan typically depends on:

- Court size (standard or customized)

- Material quality

- Glass thickness

- Lighting system

- Turf type

- Installation and labor charges

Premium courts cost more initially but save money in the long run due to reduced maintenance and increased lifespan.

Pedal Court Manufacturing Company in Lahore – The Hub of Sports Infrastructure

Lahore has become home to many reputable manufacturers offering world-class solutions. A trusted pedal court manufacturing company in Lahore provides:

- Custom court designs

- Premium-grade materials

- Professional installation services

- Competitive pricing

- After-installation maintenance

This makes Lahore a leading center for sports court development in Pakistan.

Why Choosing the Right Pedal Court Matters for Long-Term Value?

When planning to invest in a new court, many buyers focus only on the pedal court price in Pakistan, but long-term performance depends on much more than cost. Selecting a reliable installer and a top-grade pedal court manufacturer in Pakistan ensures your facility remains safe and visually appealing for many years.

A high-quality setup involves premium glass panels, durable steel framing, and specialized flooring materials. That’s why partnering with an experienced pedal court construction in Pakistan company is essential—they understand local weather conditions, soil types, and the best turf options available.

In addition to construction, the pedal court turf price plays a crucial role in overall performance. Premium turf enhances ball speed, reduces player injuries, and offers better drainage. Sports clubs, gyms, and private property owners often choose companies that provide complete service packages, including turf selection, installation, and maintenance.

For customers in Punjab, finding a reputable pedal court manufacturing company in Lahore can make the entire process smoother. These companies offer customized designs, competitive pricing, and fast installation services. With the growing demand for pedal court installation in Pakistan, the industry continues to innovate and offer better solutions for sports enthusiasts nationwide.

Conclusion

Investing in a premium quality pedal court is an excellent choice for sports clubs, academies, schools, and private home owners in Pakistan. With rising popularity and increasing local expertise, finding the right manufacturer, installer, or construction partner has never been easier.

Whether you are searching for pedal court price in Pakistan, reliable pedal court installation in Pakistan, or a trusted pedal court manufacturing company in Lahore, choosing quality ensures the best playing experience for years to come.

FAQ’S

How much does a padel court cost?

A single padel court typically costs $24,000 to $65,000 to build, depending on materials, glass walls, turf, lighting, and groundwork.

How much does it cost to build a padel court in Pakistan?

Building a padel court in Pakistan typically costs around PKR 10 million to PKR 15 million, depending on the quality of turf, glass walls, lighting, and other materials

How much is the padel court in Lahore?

Private padel courts in Lahore (e.g., Padel Café) charge around PKR 4,000/hour off‑peak and PKR 5,000/hour in peak times.

How much does an instant padel court cost?

An instant padel court (modular, pop-up design) costs around PKR 11.5–12 million.

Smaller or simpler modular courts (less glass, lighter structure) cost approximately PKR 2–3 million.