Durable, hygienic, and easy to maintain — our hospital flooring ensures a safe, sterile, and comfortable environment for patients and staff alike.

Our Gallery

Covering Wall To Wall

01

Self-Leveling Epoxy Floors

Self-leveling epoxy floors are created by combining epoxy resin with a hardening agent and other additives. The resulting mixture has a low viscosity and is designed to flow and self-level across a substrate

03

Metallic Epoxy Floors

Metallic epoxy floors are created by mixing metallic pigments or powders into epoxy resin. These pigments come in various colors, including gold, silver, bronze, and vibrant hues.

02

Epoxy Flake Floors

Epoxy flake floors, also known as decorative flake floors or epoxy chip floors, are a type of flooring system that combines epoxy resin with decorative flakes to create a visually appealing and durable surface.

Apartments

Commercial Projects

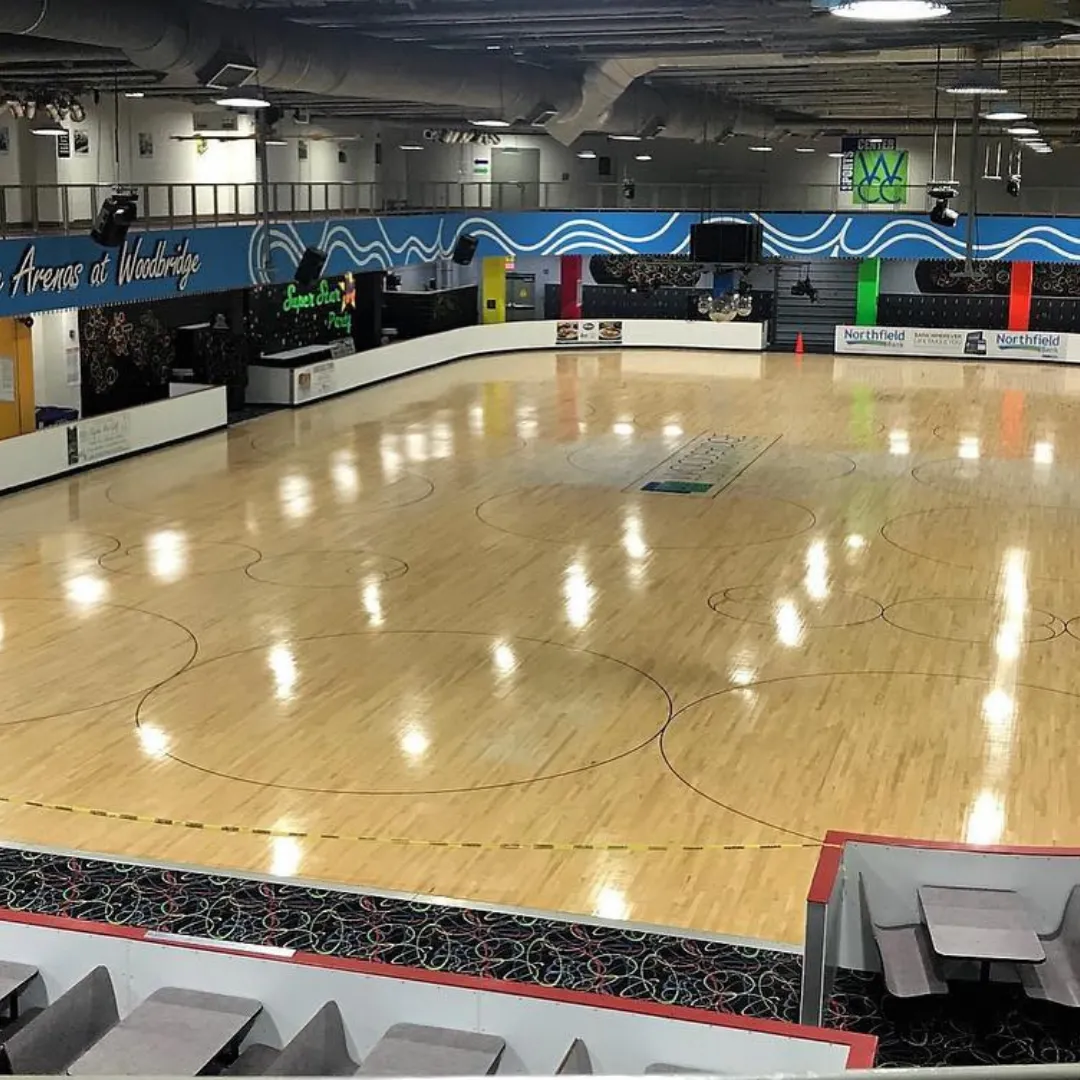

Sports Complex

Resorts & Enclosures

Contemporary and Stylish

TIMELESS CLASSIC FINISH

YOU WOULD LOVE TO WALK ON

Household interiors and business spaces can benefit from these finishes’ timeless and traditional appeal. Working with a qualified epoxy flooring contractor is essential if you want to achieve the desirable timeless aesthetic you’re going for. They can help you choose the appropriate colours, patterns, and application methods.

STURDY & UTILITARIAN

EXEMPLARY WORKMANSHIP

It is vital to take into account aspects like the intended use of the space, the volume of foot traffic, and any particular requirements for resistance to chemicals, moisture, or impact when selecting a sturdy and ultra-durable flooring solution. You can choose the best alternative for your needs by speaking with professionals in flooring.

Our Services

Some of Our Skills

What We Offer

Operation Theather Flooring

Our OT flooring provides a seamless, anti-bacterial, and anti-static surface designed to maintain strict hygiene standards in operation theaters.

Our Projects

Our Expertise, A Tribute to Success

News & Blog

what is epoxy floor & What is epoxy flooring price in pakistan

An epoxy floor is a type of flooring system made by applying a layer of epoxy resin over a concrete surface. The resin is a two-part compound consisting of an epoxy resin and a polyamine hardener, which react to form a durable and resistant coating. Here’s what makes epoxy flooring popular:we provide affordable epoxy flooring price in pakistan

Key Features

- Durability: Epoxy floors are highly resistant to wear and tear, making them suitable for heavy traffic areas.

- Chemical Resistance: They can withstand exposure to many chemicals, making them ideal for industrial and commercial applications.

- Aesthetic Appeal: Epoxy floors can be customized with a variety of colors, patterns, and decorative options such as metallic finishes or flake systems.

- Seamless and Easy to Clean: The non-porous, smooth surface is easy to maintain and does not harbor bacteria, making it suitable for environments like hospitals and kitchens.

- Water and Stain Resistance: Epoxy coating forms a waterproof and stain-resistant barrier over the concrete.

Common Uses

- Garages: Epoxy floors are popular in garages due to their durability and ability to withstand vehicle fluids.

- Commercial Spaces: Warehouses, restaurants, and shopping malls use epoxy for its aesthetic versatility and resilience.

- Industrial Settings: Factories and production areas benefit from its resistance to chemicals and heavy machinery.

- Residential Areas: Epoxy is increasingly used in homes, especially in basements, kitchens, or bathrooms. epoxy flooring price in pakistan

Types of epoxy floor

There are several types of epoxy floors, each designed for different uses and environments. Here’s an overview of the most common types:

1. Self-Leveling Epoxy Floors

Self-leveling epoxy flooring is a popular and highly durable flooring solution used in both residential and commercial spaces. This type of floor coating is known for its smooth, seamless, and high-gloss finish, which makes it ideal for environments that require both aesthetic appeal and functionality.fin best epoxy flooring price in pakistan

Benefits of Self-Leveling Epoxy Floors

- Durability: Epoxy floors are extremely strong and resistant to wear, making them suitable for high-traffic areas.

- Chemical Resistance: Ideal for industrial environments where exposure to chemicals is common.

- Ease of Maintenance: The smooth, non-porous surface makes it easy to clean and maintain.

- Aesthetic Appeal: Available in various colors, patterns, and finishes, making it a versatile choice for design customization.

- Seamless Finish: Helps in reducing dirt and bacteria buildup, ideal for sterile environments like hospitals or laboratories.

Common Uses

- Garages: Provides a tough, durable finish that withstands vehicle traffic and oil spills.

- Warehouses: Resists heavy machinery and frequent foot traffic.

- Showrooms: Enhances the appearance of spaces with a sleek, polished look.

- Commercial Kitchens: Non-porous and resistant to spills and stains.

Installation Process

- Surface Preparation: The existing surface must be clean, dry, and free of any contaminants. Any cracks or holes should be repaired.

- Priming: A primer is applied to ensure good adhesion between the substrate and the epoxy.

- Mixing: The self-leveling epoxy resin and hardener are mixed thoroughly.

- Application: The mixture is poured onto the floor and spread using a roller or squeegee. It self-levels to create a uniform surface.

- Curing: The floor is left to cure, which typically takes 24-48 hours, depending on the specific product and environmental conditions.get qoute for epoxy flooring price in pakistan

2-Metallic Epoxy Floor

4-Anti-Static Epoxy Floors (ESD Epoxy)

Anti-static epoxy floors, also known as ESD (Electrostatic Discharge) epoxy floors, are specially formulated flooring systems designed to prevent the buildup and discharge of static electricity. These floors are essential in environments where static electricity could pose a hazard to sensitive electronic equipment, ignite flammable substances, or disrupt critical processes. ESD epoxy flooring systems combine the durability and ease of maintenance of traditional epoxy floors with advanced electrostatic control capabilities.get epoxy flooring price in pakistan

What are Anti-Static Epoxy Floors?

Anti-static epoxy floors are created by incorporating conductive materials into the epoxy coating, which allows static electricity to dissipate safely to the ground. This controlled dissipation prevents the buildup of static charges, protecting both personnel and equipment. These floors are available in a variety of colors and finishes, making them both functional and visually appealing.find epoxy flooring price in pakistan

How Anti-Static Epoxy Flooring Works

ESD epoxy floors are designed with materials that conduct electricity and provide a path for static electricity to flow to a grounding point. The flooring contains conductive additives, such as carbon fibers or metallic components, that help in redirecting static charges. The floor is often connected to an electrical grounding system to ensure that any built-up static electricity is safely discharged.

Benefits of Anti-Static Epoxy Floors

- Electrostatic Protection: The primary benefit of anti-static epoxy floors is their ability to prevent electrostatic discharge. This is crucial for protecting sensitive electronics, preventing damage to critical equipment, and reducing the risk of fires or explosions in hazardous environments.

- Durability: Like standard epoxy floors, anti-static epoxy is highly durable and can withstand heavy machinery, high foot traffic, and impact, making it suitable for industrial settings.

- Chemical Resistance: ESD epoxy floors are resistant to a variety of chemicals, oils, and solvents, making them easy to clean and maintain.

- Hygienic and Seamless: These floors provide a seamless surface that is resistant to bacteria, dust, and dirt accumulation, making them suitable for cleanrooms and pharmaceutical facilities.

- Low Maintenance: ESD epoxy floors are easy to clean with regular sweeping and occasional mopping. The durable, non-porous surface resists stains and does not require frequent refinishing.

- Safety: In addition to static control, these floors offer other safety features, such as slip resistance, which can be enhanced by adding a textured topcoat.

Common Applications

- Electronics Manufacturing: ESD epoxy floors are essential in environments where sensitive electronic components are manufactured, assembled, or handled. They help prevent costly damage to circuit boards and microchips caused by static electricity.

- Data Centers: Data centers use anti-static flooring to protect servers and other equipment from electrostatic discharge, ensuring continuous and reliable operation.

- Cleanrooms: Pharmaceutical and biotechnology facilities use anti-static epoxy floors to maintain a controlled environment, where static control and hygiene are critical.

- Laboratories: In chemical and research labs, ESD epoxy floors provide safety by preventing the ignition of flammable substances due to static sparks.

- Aerospace and Defense: These industries often require ESD protection for the manufacturing and testing of sensitive equipment and components.

- Automotive Industry: ESD flooring is used in areas where sensitive electronic car components are developed and assembled.

Installation Process

- Surface Preparation: Proper preparation is crucial for effective adhesion. The surface is cleaned, repaired, and sometimes mechanically ground to ensure the epoxy bonds well with the substrate.

- Priming: A conductive or ESD primer is applied to the prepared surface. This primer helps to enhance adhesion and provides the initial layer of static control.

- Base Coat: A base coat of anti-static epoxy is applied. This layer may contain conductive materials that help dissipate static electricity.

- Conductive Grid: In some installations, a conductive grid or copper strips are installed to create a direct path for static electricity to be grounded.

- Topcoat Application: A final ESD topcoat is applied to seal the floor and provide a durable, protective finish. The topcoat ensures long-lasting electrostatic control and enhances the floor’s chemical and abrasion resistance.

Design and Customization

While ESD epoxy floors are functional, they do not have to sacrifice aesthetics. They are available in various colors and finishes, allowing you to maintain a cohesive design within your facility. Custom line markings, patterns, and logos can also be incorporated to enhance safety or branding.find epoxy flooring price in pakistan

Compliance and Standards

ESD epoxy flooring systems must comply with industry standards for static control. Common standards include ANSI/ESD S20.20 and IEC 61340, which outline the requirements for electrostatic discharge control in various settings. Compliance with these standards ensures that your flooring system provides adequate protection for your specific application.

Anti-static epoxy floors are a practical and reliable solution for environments where static electricity poses a risk to people, equipment, or processes. Their combination of durability, ease of maintenance, and advanced static control capabilities make them an essential investment for high-tech, industrial, and safety-sensitive environments.

5-Quartz-Filled Epoxy Floor

6-Epoxy Mortar Floor

Epoxy mortar floors are the most robust and durable epoxy flooring systems available, designed to withstand extreme conditions and heavy loads. Made from 100% solid epoxy combined with graded sand or quartz aggregates, this flooring system creates a high-strength mortar that provides exceptional resistance to impact, abrasion, and chemical exposure. Epoxy mortar floors are ideal for environments that require a heavy-duty flooring solution, such as warehouses, manufacturing facilities, commercial kitchens, and garages.

What is an Epoxy Mortar Floor?

Epoxy mortar floors are a troweled flooring system consisting of multiple layers of epoxy and graded aggregates. The result is a seamless, non-porous, and incredibly durable surface that can handle the harshest industrial conditions. This type of flooring is commonly used to repair and level damaged concrete surfaces, creating a solid foundation that can endure both mechanical and thermal stresses.

Key Benefits of Epoxy Mortar Floors

- Unmatched Durability: Epoxy mortar floors are engineered for maximum strength and durability, capable of withstanding heavy machinery, forklifts, and high-impact loads without cracking or chipping. They are perfect for high-traffic industrial areas.

- Chemical and Abrasion Resistance: The chemical-resistant properties of epoxy mortar flooring make it ideal for facilities that deal with corrosive chemicals, oils, and solvents. It also resists scratches and wear from heavy use.

- Thermal Shock Resistance: This flooring system can handle rapid temperature fluctuations, making it suitable for environments like commercial kitchens and food processing plants.

- Seamless and Hygienic: The seamless, non-porous surface prevents the accumulation of dirt, bacteria, and moisture, which is essential in environments where cleanliness is a top priority, such as pharmaceutical and food manufacturing facilities.

- Slip Resistance: To ensure safety in high-risk areas, epoxy mortar floors can be textured for added slip resistance. This feature is particularly important in settings where liquids are frequently spilled, such as car service stations and laboratories.

- Repair and Leveling Capabilities: Epoxy mortar is often used to repair and resurface damaged or uneven concrete floors, creating a smooth and level surface that is stronger than the original substrate. epoxy flooring price in pakistan

Common Applications

- Manufacturing Facilities: These floors are perfect for industrial settings where heavy machinery and equipment are used regularly, providing a surface that can withstand continuous abuse.

- Warehouses: Epoxy mortar floors are ideal for warehouses that experience constant forklift traffic and heavy pallet loads, ensuring the flooring remains intact and safe for operations.

- Commercial Kitchens: The thermal shock resistance and easy-to-clean surface make epoxy mortar flooring suitable for kitchens, where hot water and grease spills are common.

- Automotive Workshops and Garages: These floors are resistant to oil, grease, and chemical spills, making them a practical choice for automotive facilities and car service centers.

- Food and Beverage Processing: The seamless, hygienic, and chemical-resistant properties are perfect for food processing plants where cleanliness and safety are essential.

- Airplane Hangars: The flooring’s strength and resistance to fuel, oil, and heavy loads make it suitable for aviation facilities.

Installation Process

- Surface Preparation: Proper surface preparation is critical for the success of an epoxy mortar floor. The concrete substrate must be cleaned and profiled, often using mechanical grinding or shot blasting, to ensure good adhesion. Any existing cracks, holes, or damage are repaired.

- Primer Application: A primer coat of epoxy is applied to the prepared surface to enhance adhesion and seal the concrete. This layer ensures that the mortar bonds effectively with the substrate.

- Mortar Application: The epoxy mortar mix, which consists of epoxy resin, hardener, and graded aggregates, is applied with a trowel. This layer is spread and smoothed to the desired thickness, typically between 1/4 and 3/8 inch (6 to 9 mm), depending on the application requirements.

- Topcoat Application: Once the mortar layer has cured, a topcoat of epoxy is applied to seal and protect the surface. This topcoat can be customized with added slip-resistant textures or made glossy for a polished look. The final coat enhances the floor’s durability and chemical resistance.

- Curing: The floor is left to cure, which can take several days, depending on the environment and the specific epoxy product used. Proper curing ensures the floor achieves maximum strength and performance.

Design and Customization

While epoxy mortar floors are primarily installed for their functionality, they can also be customized to fit the aesthetic needs of a space. Color options are available to match facility branding or to designate specific areas, such as safety zones or walkways. For added safety, textured surfaces can be incorporated, or smooth finishes can be selected for easier cleaning in less hazardous areas.

Maintenance and Longevity

Epoxy mortar floors are low maintenance but require some routine care to maximize their lifespan. Regular sweeping and occasional mopping with a neutral cleaner will keep the surface clean and in good condition. Thanks to their exceptional durability, epoxy mortar floors can last for decades, even under the most demanding conditions, making them a cost-effective investment for facilities that require heavy-duty performance.

Safety Considerations

Epoxy mortar floors can be modified to improve safety features, such as slip resistance, which is crucial in environments where wet or slippery conditions are common. In addition, these floors provide a level, uniform surface, reducing the risk of tripping hazards in busy work areas.

Epoxy mortar floors are one of the strongest and most resilient flooring systems available, offering unparalleled performance in the harshest environments. Their ability to withstand heavy loads, resist chemicals, and provide a seamless and hygienic surface makes them ideal for industrial, commercial, and high-traffic settings. Whether you need to protect a new concrete surface or repair and reinforce an existing one, epoxy mortar floors deliver a long-lasting, durable solution tailored to your specific needs.get qoute for epoxy flooring price in pakistan

Transform Your Space with High-Quality Epoxy Flooring in Pakistan

In recent years, there has been a significant increase in the demand for durable and aesthetically epoxy flooring solutions in Pakistan. One of the leading companies catering to this demand is Unicorn Epoxy Flooring, which offers high quality epoxy flooring services in Lahore, Islamabad and Karachi. With its commitment to quality and customer satisfaction, Unicorn Epoxy Flooring has become a trusted name in the industry.

Growing Epoxy Flooring in Pakistan

Due to its versatility and many advantages, epoxy flooring has gained popularity in Pakistan. Homeowners, businesses and industrial spaces are increasingly turning to epoxy flooring because of its durability, ease of maintenance and aesthetics. Unicorn Epoxy Flooring has proven itself as a leader in high quality epoxy flooring solutions tailored to the unique needs of customers nationwide.

Services offered by Unicorn Epoxy Flooring

Residential Epoxy Flooring in Pakistan

Unicorn Epoxy Flooring understands the importance of providing durable and attractive flooring for homes. They offer epoxy flooring options for living areas, including kitchens, living rooms and garages. Whether it’s a modern and sleek look or a more traditional design, Unicorn Epoxy Flooring has the knowledge to bring your vision to life.

Commercial Epoxy Flooring in Pakistan

Companies from Lahore, Islamabad and Karachi turn to Unicorn Epoxy Flooring for their commercial flooring needs. From retail and office spaces to warehouses and showrooms, Unicorn Epoxy Flooring offers durable, low-maintenance solutions that can withstand heavy foot traffic and help create a professional environment.

Industrial Epoxy Flooring in Pakistan

Industries in Pakistan need durable flooring solutions that can withstand the demands of heavy machinery, chemicals and daily use. Unicorn Epoxy Flooring in Pakistan specializes in industrial epoxy flooring, offering abrasion, chemical and impact resistant options. To ensure a safe and durable environment for workers.

Why did you choose Unicorn Epoxy Flooring?

Expertise

With years of experience in the industry, Unicorn Epoxy Flooring boasts a team of experienced professionals who understand the incredible properties of epoxy flooring and are able to deliver exceptional results.

Quality Materials

Unicorn Epoxy Flooring uses only the highest quality materials to ensure durability and performance. Their epoxy coatings are known for their durability and resistance.

Customization

Every space is unique, and Unicorn Epoxy Flooring recognizes the importance of customization. They work closely with customers to understand their preferences and provide tailored solutions tailored to their specific needs.

Completion Time

Unicorn Epoxy Flooring values your time and strives to complete projects within the agreed upon timeline. Their effective and professional approach ensures that you won’t disrupt a few of your daily routines.

Conclusion

Unicorn Epoxy Flooring stands out as a trusted and reputed company providing epoxy flooring solutions in Pakistan. Whether you want to improve the aesthetics of your home. Create a professional atmosphere in your business, or strengthen your technical standing, Unicorn Epoxy Flooring has the knowledge and commitment to deliver exceptional results. Transform your space with durable, attractive, and easy-to-maintain epoxy flooring from Unicorn Epoxy Flooring.

we give good epoxy flooring price in pakistan

Epoxy Floors in Lahore, Pakistan: The Ultimate Flooring Solution

Epoxy floors have become increasingly popular in Lahore, Pakistan, due to their durability, versatility, and sleek finish. Whether you’re looking to upgrade your home, office, or industrial space, epoxy flooring offers a long-lasting, cost-effective solution that’s both stylish and practical. In this article, we’ll explore what epoxy floors are, their benefits, and why they’re an ideal choice for both residential and commercial spaces in Lahore.

What Are Epoxy Floors?

Epoxy flooring is a type of surface coating that is made from a mixture of resin and hardener. When these two components are combined, they form a chemical bond that creates a strong, durable surface. This coating is applied over concrete floors, making them resistant to wear and tear, stains, and chemical spills. It provides a glossy, smooth finish that’s easy to clean and maintain, which is why it’s becoming a popular choice for many spaces in Lahore, including homes, showrooms, and factories.

Benefits of Epoxy Floors

- Durability: One of the biggest advantages of epoxy flooring is its strength and resilience. It can withstand heavy foot traffic, making it ideal for areas like factories, garages, and warehouses.

- Easy to Maintain: Epoxy floors are resistant to dust, dirt, and stains, which means they require minimal cleaning. A simple sweep or mop is enough to keep them looking new.

- Aesthetic Appeal: The glossy finish of epoxy flooring gives any space a modern and professional look. You can choose from a variety of colors and patterns to match your interior design.

- Chemical Resistance: Epoxy flooring is highly resistant to chemicals, which makes it perfect for industrial areas where harsh chemicals are often used.

- Affordability: Compared to other types of flooring, epoxy is a cost-effective option that provides excellent value for money due to its longevity.

Epoxy Flooring in Lahore, Pakistan

Lahore is a city that blends tradition with modernity, and many businesses and homeowners are now opting for epoxy flooring because of its durability and aesthetic appeal. Whether you’re looking to install epoxy floors in your home, garage, or commercial space, there are numerous providers offering epoxy flooring services in Lahore. From small residential projects to large-scale industrial floors, epoxy is versatile enough to meet any need.

Why Choose Epoxy Flooring for Your Lahore Property?

- Seamless Finish: With no joints or seams, epoxy floors are easy to clean and maintain, making them perfect for both homes and commercial spaces in Lahore.

- Customizable: Epoxy floors can be customized with different colors, textures, and designs, allowing you to create a unique look that complements your space.

- Quick Installation: Epoxy floors can be installed relatively quickly, minimizing disruption to your daily life or business operations.

Popular Epoxy Flooring Searches in Lahore, Pakistan

If you’re searching for epoxy flooring services in Lahore, you might come across terms like:

- Best Epoxy Floors in Lahore

- Affordable Epoxy Flooring Lahore

- Epoxy Floor Installers in Lahore

- Industrial Epoxy Flooring Lahore

- Home Epoxy Flooring Lahore

These keywords reflect the growing demand for epoxy flooring in various settings across the city. By choosing the right epoxy flooring provider, you can ensure that your floors will last for years while maintaining a stylish and modern appearance.we provide best epoxy flooring price in pakistan